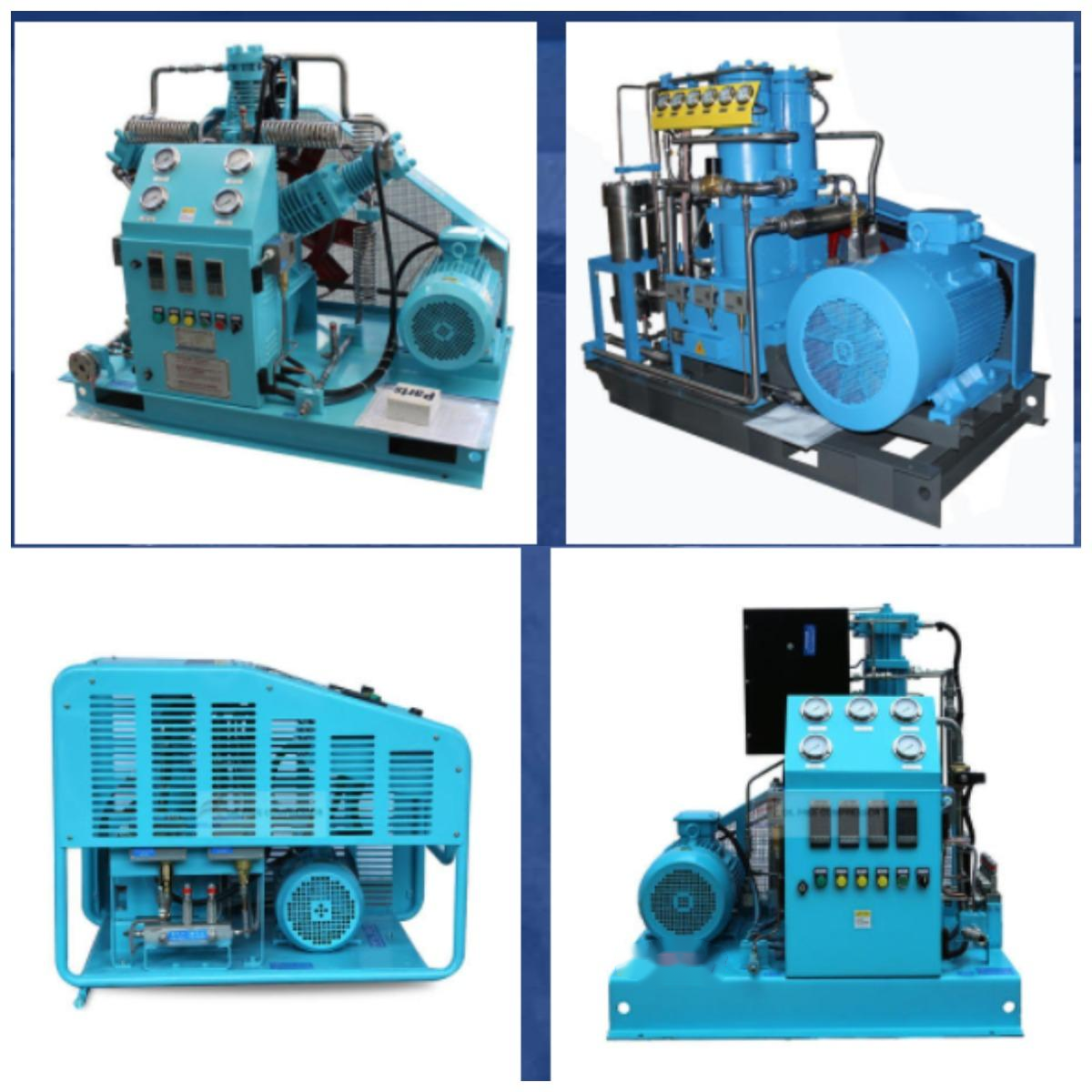

4 Stage High Pressure Reciprocating Piston compressor for bottle Filling System

The gas compressor is suitable for a variety of gas pressurization, transportation and other working conditions. Suitable for medical, industrial, flammable and explosive, corrosive and toxic gases.

The oil-free oxygen compressor adopts a completely oil-free design. The friction seals such as piston ring and guide ring are made of special materials with self-lubricating characteristics. The compressor adopts four-stage compression, water-cooled cooling method and stainless steel water cooler to ensure a good cooling effect of the compressor and effectively extend the service life of key wearing parts. The intake port is equipped with a low intake pressure, and the exhaust end is equipped with an exhaust device. Each level of high pressure protection, high exhaust temperature protection, safety valve and temperature display. If the temperature is too high and overpressure, the system will alarm and stop to ensure safe operation.

We have CE certificate. We can also provide customized oxygen compressors according to customer conditions.

◎The entire compression system has no thin oil lubrication, which avoids the possibility of oil contacting high-pressure and high-purity oxygen and ensures the safety of the machine;

◎The whole system has no lubrication and oil distribution system, the machine structure is simple, the control is convenient, and the operation is convenient;

◎The whole system is oil-free, so the compressed medium oxygen is not polluted, and the purity of the oxygen at the inlet and outlet of the compressor is the same.

◎Low purchase cost, low maintenance cost and simple operation.

◎It can run stably for 24 hours without shutting down (depending on the specific model)

OIL-FREE OXYGEN COMPRESSOR-PARAMETER TABLE

Oxygen compressor refers to a compressor used to pressurize oxygen and realize transportation or storage. There are two types of general medical oxygen compressors.

One is that the hospital's PSA oxygen generator needs to be pressurized to supply various wards and operating rooms.It provides 7-10 bar of pipeline pressure.

Another type of PSA oxygen needs to be stored in a high-pressure container for convenient use. The storage pressure is generally 100 barg,150barg,200barg, or a higher pressure of 300barg.

Industrial applications for this oxygen compressor machine include low or medium pressure oxygen compressor systems for VSA applications in steel mill, paper mills and water treatment plants.

Fully bottle cylinder filling oxygen compressor, air-cooled and water-cooled two cooling modes, single-action and double-acting structure. vertical and angle type, wind type series high pressure oil-free lubrication Oxygen compressor, excellent performance, stable operation. high efficiency and energy saving, long service life, widely used in oxygen tanking, chemical process and plateau oxygen supply, together with oxygen generator to form a simple and safe high-pressure oxygen system.

The friction pairs of the series of machines involved in gas compression are not lubricated with thin oil. The friction seals such as piston rings and guide rings are made of special materials with self-lubricating properties. The structural advantages are reflected in:

1.There is no thin oil lubrication in the whole compression system, which avoids the possibility of oil contact with high pressure and high purity oxygen, and ensures the safety of the machine:

2.The whole system has no lubrication and oil distribution system, the machine structure is simple, the control is convenient, and it is easy to operate;

3.The whole system is oil-free,so the compressed medium, oxygen, is non-polluting,and the oxygen purity of the inlet and outlet of the compressor is the same.

Features of our oxygen compressor :

1.CE and ISO13485 certification is available for all standard filling high pressure oxygen compressor to meet the requirements of the EU market .

2.Completely 100% oil free, no oil required (depending on the specific model) .

3.Cylinder Cast stainless steel.

4.Low maintenance cost and simple operation.

5.4000 hours piston ring working life under low pressure conditions,1500-200O hours working life under high pressure conditions.

6.TOP brand motor .

7.According to the customer's specific working conditions, the compressor is designed for single machine compression,two-stage compression, three-stage compression and four-stage compression.

8. Low speed, long life, average speed 260-350RPM.

9.Low noise, average noise below 75dB, can work quietly in the medical field .

10.Continuous continuous heavy-duty operation, can run stably for 24 hours without stopping .

Each stage has an interstage safety valve, If the stage is overpressured. the safety valve will take off and release the overpressure gas to ensure the stable operation of the compressor

PARAMETERS

| Model | Medium | Intake pressure barg | Exhaust pressure barg | Flow-rate Nm3/h | Motor Power KW | Air Inlet/Outlet Size mm | Cooling method | Weight kg | Dimensions (L×W×H)mm |

| GOW-30/4-150 | Oxygen | 3-4 | 150 | 30 | 11 | DN25/M16X1.5 | Water-cooled/Air-cooled | 750 | 1550X910X1355 |

| GOW-40/4-150 | Oxygen | 3-4 | 150 | 40 | 11 | DN25/M16X1.5 | Water-cooled/Air-cooled | 780 | 1550X910X1355 |

| GOW-50/4-150 | Oxygen | 3-4 | 150 | 50 | 15 | DN25/M16X1.5 | Water-cooled/Air-cooled | 800 | 1550X910X1355 |

| GOW-60/4-150 | Oxygen | 3-4 | 150 | 60 | 18.5 | DN25/M16X1.5 | Water-cooled/Air-cooled | 800 | 1550X910X1355 |

SUBMIT INQUIRY PARAMETERS

If you want us to provide you with detailed technical design and quotation, please provide the following technical parameters, and we will reply to your email or phone within 24 hours.

1.Flow: _____ Nm3 / hour

2.Inlet pressure: _____Bar(MPa)

3.Outlet pressure: _____Bar(MPa)

4. Gas medium: _____

We can customize a variety of compressors. Please send the above parameters to email: Mail@huayanmail.com