High Purity Oxygen Diaphragm Compressor

Reciprocating Completely Oil-Free Diaphragm Compressor

Our company specialize in making various kinds of compressors, such as:Diaphragm compressor,Piston compressor, Air compressors,Nitrogen generator,Oxygen generator ,Gas cylinder,etc. All products can be customized according to your parameters and other requirements.

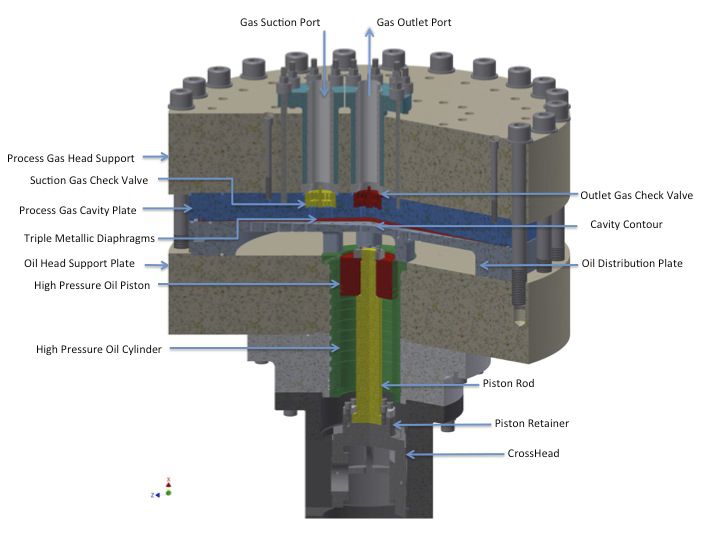

Process principle

Diaphragm compressor according to the needs of the user, choose the right type of compressor to meet the needs of the user. The diaphragm of the metal diaphragm compressor completely separates the gas from the hydraulic oil system to ensure the purity of the gas and no pollution to the gas. At the same time, advanced manufacturing technology and accurate membrane cavity design technology are adopted to ensure the service life of the diaphragm compressor diaphragm. No pollution: the metal diaphragm group completely separates the process gas from the hydraulic oil and lubricating oil parts to ensure the gas purity.

Main Structure

Diaphragm compressor structure is mainly composed of motor, base, crankcase, crankshaft linkage mechanism, cylinder components, crankshaft connecting rod, piston, oil and gas pipeline, electric control system and some accessories.

Gas Media type

Our compressors can compress ammonia, propylene, nitrogen, oxygen, helium, hydrogen, hydrogen chloride, argon, hydrogen chloride, hydrogen sulfide, hydrogen bromide, ethylene, acetylene, etc.(Nitrogen diaphragm compressor,bottle filling compressor,oxygen diaphragm compressor)

Advantages

1.Good sealing performance

Diaphragm compressor is a kind of special structure displacement compressor.The gas does not need lubrication,the sealing performance is good,the compression medium does not contact with any lubricant,and there will be no pollution in the compression process.It is especially suitable for high purity(99.9999%),rate,extremely corrosive,toxic and harmful,inflammable and explosive.Compression,transportation and bottle filling of radioactive gases.Membrane head is sealed with inlaid double O-ring,and its sealing effect is far better than that of open type.

2.Cylinder has good heat dissipation performance

The working cylinder of diaphragm compressor has good heat dissipation performance and is close to isothermal compression.It can adopt higher compression ratio and is suitable for compressing high-pressure gas.

3.Compressor speed is low and service life of vulnerable parts is prolonged.The new type of diaphragm cavity curve improve the volume efficiency of the compressor,optimize the value type,and adopt special heat treatment method for diaphragm,which greatly improves the service life of the compressor.

4.The high efficiency cooler is adopted,which makes the whole machine low in temperature and high in efficiency.The service life of lubricating oil,O-ring and value spring can be prolonged appropriately .Under the condition of meeting the buyer's technological parameters,the structure is more advanced,reasonable and energy-saving.

5.The diaphragm rupture alarm structure is advanced,reasonable and reliable.The diaphragm installation has no directionality and is easy to replace.

6.The parts and components of the whole equipment are concentrated on a skid-mounted chassis,which is convenient for transportation,installation and management.

GV series diaphragm compressor :

Structure type : V type

Piston Travel : 70-130mm

Max Piston force : 10KN-30KN

Max discharge Pressure : 50MPa

Flow Rate Range :2-100Nm3/h

Motor Power : 2.2KW-30KW

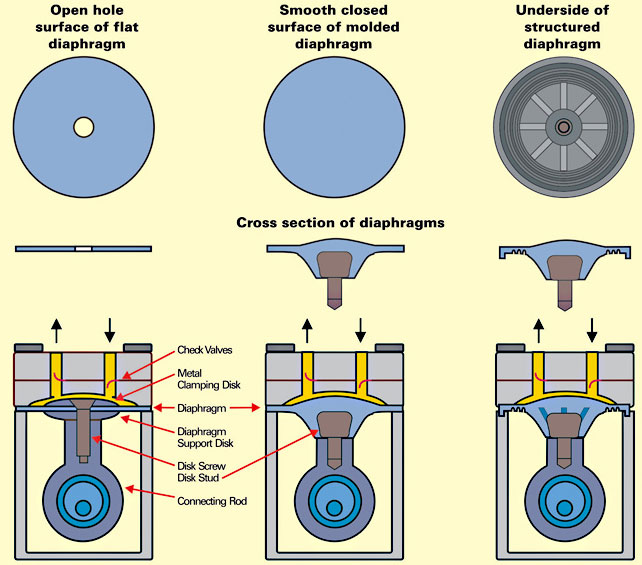

The compressoris consists of athree pieces of diaphragms. The diaphragm is clamped along the surrounding area by the hydraulic oil side and the process gas side of the process. The diaphragm is driven by the hydraulic driver in the film head to achieve the compression and transportation of the gas. The main body of the diaphragm compressor consists of two systems: the hydraulic oil system and the gas compression system, and the metal membrane separates these two systems.

Basically, the structure of the diaphragm compressor is divided into two parts: the hydraulic framework and the pneumatic force framework. During the compression process, there are two steps: the suction stroke and the delivery stroke.

Reference specification

| Model | Cooling water consumption (t/h) | Displacement (Nm³/h) | Intake pressure (MPa) | Exhaust pressure (MPa) | Dimensions L×W×H(mm) | Weight (t) | Motor Power (kW) | |

| 1 | GL-10/160 | 1 | 10 | atmo | 16 | 2200×1200×1300 | 1.6 | 7.5 |

| 2 | GL-25/15 | 1 | 25 | tomo | 1.5 | 2200×1200×1300 | 1.6 | 7.5 |

| 3 | GL-20/12-160 | 1 | 20 | 1.2 | 16 | 2200×1200×1300 | 1.6 | 7.5 |

| 4 | GL-70/5-35 | 1.5 | 70 | 0.5 | 3.5 | 2000×1000×1200 | 1.6 | 15 |

| 5 | GL-20/10-150 | 1.5 | 20 | 1.0 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 6 | GL-25/5-150 | 1.5 | 25 | 0.5 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 7 | GL-45/5-150 | 2 | 45 | 0.5 | 15 | 2600×1300×1300 | 1.9 | 18.5 |

| 8 | GL-30/10-150 | 1.5 | 30 | 1.0 | 15 | 2300×1300×1300 | 1.7 | 11 |

| 9 | GL-30/5-160 | 2 | 30 | 0.5 | 16 | 2800×1300×1200 | 2.0 | 18.5 |

| 10 | GL-80/0.05-4 | 4.5 | 80 | 0.005 | 0.4 | 3500×1600×2100 | 4.5 | 37 |

| 11 | GL-110/5-25 | 1.4 | 110 | 0.5 | 2.5 | 2800×1800×2000 | 3.6 | 22 |

| 12 | GL-150/0.3-5 | 1.1 | 150 | 0.03 | 0.5 | 3230×1770×2200 | 4.2 | 18.5 |

| 13 | GL-110/10-200 | 2.1 | 110 | 1 | 20 | 2900×2000×1700 | 4 | 30 |

| 14 | GL-170/2.5-18 | 1.6 | 170 | 0.25 | 1.8 | 2900×2000×1700 | 4 | 22 |

| 15 | GL-400/20-50 | 2.2 | 400 | 2.0 | 5.0 | 4000×2500×2200 | 4.5 | 30 |

| 16 | GL-40/100 | 3.0 | 40 | 0.0 | 10 | 3700×1750×2000 | 3.8 | 30 |

| 17 | GL-900/300-500 | 3.0 | 900 | 30 | 50 | 3500×2350×2300 | 3.5 | 55 |

| 18 | GL-100/3-200 | 3.5 | 100 | 0.3 | 20 | 3700×1750×2150 | 5.2 | 55 |

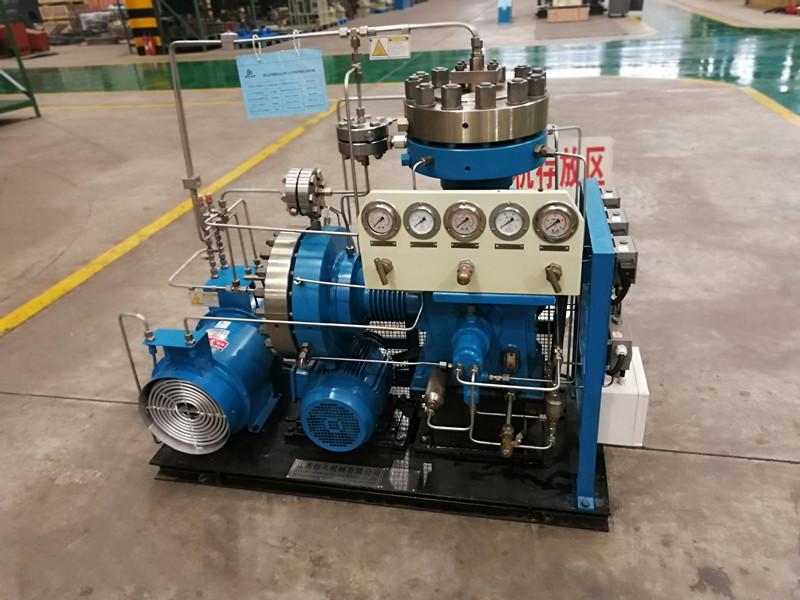

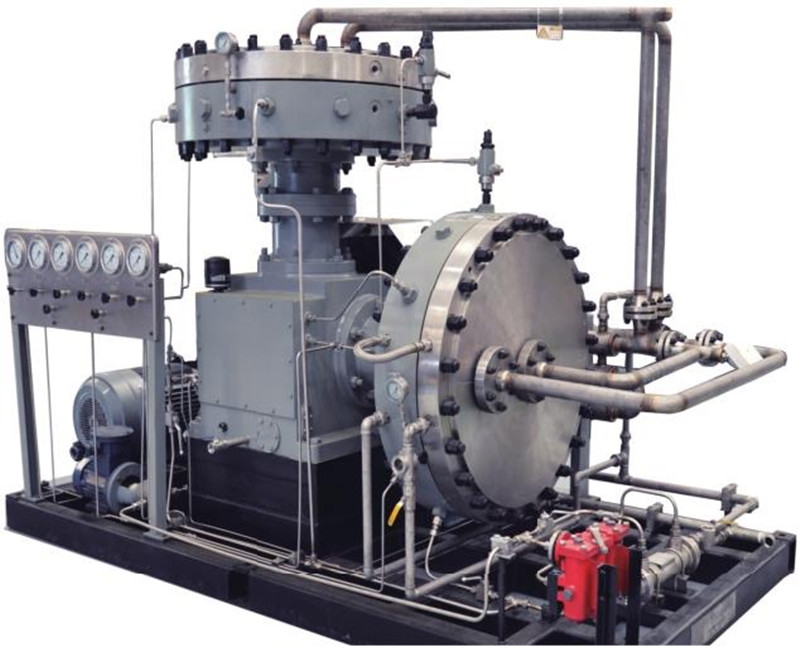

Picture display

RFQ

1.How to get a prompt quotation of gas compressor ?

1)Flow Rate/Capacity : ___ Nm3/h

2)Suction/ Inlet Pressure : ____ Bar

3)Discharge/Outlet Pressure :____ Bar

4)Gas Medium :_____

5)Voltage and Frequency : ____ V/PH/HZ

2.How long is delivery time ?

Delivery time is around the 30-90 days .

3.What about the voltage of products? Can they be customized?

Yes, the voltage can be customized according to your inquire.

4.Can you accept OEM orders?

Yes, OEM orders is highly welcome.

5.Will you provide some spare parts of the machines?

Yes, we will .