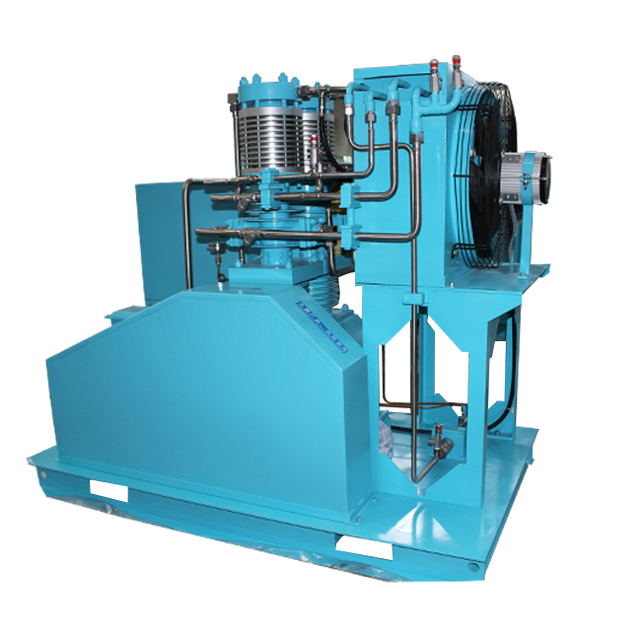

Low Noise, Long Life 4-Stage Oxygen Compressor for Cylinder Filling System

Product Description

Our company is a leading provider of oil-free gas compressor system solutions in China, and a professional high-tech enterprise that develops and produces oil-free compressors. The company has a complete marketing service system and strong continuous research and development capabilities. The products cover all oil-free lubrication. Air compressors, oxygen compressors, nitrogen compressors, hydrogen compressors, carbon dioxide compressors, helium compressors, argon compressors, sulfur hexafluoride compressors and more than 30 kinds of gas chemical compressors, the maximum pressure can reach 35Mpa. At present, many wind brand oil-free compressors produced by our company ,and have been exported to Europe, America, Japan, South Korea, Southeast Asia , More than 40 countries and regions in the Middle East and Africa, and our products have been won wide praise from many customers, and established a good reputation of quality in the hearts of users.

Oxygen compressor refers to a compressor used to pressurize oxygen and realize transportation or storage.

There are two types of commonly used medical oxygen compressors. One is that the PSA oxygen generator in the hospital needs to be pressurized to supply various wards and operating rooms. It provides a pipeline pressure of 7-10 kg. The oxygen from a PSA needs to be stored in a high-pressure container for convenient use. The storage pressure is usually 100 barg, 150 barg, 200 barg or 300 barg pressure.

The oil-free oxygen bottle filling compression is divided into two cooling methods, air-cooled and water-cooled. Vertical structure. Our company's series of high-pressure oil-free lubricated oxygen compressors have excellent performance, stable operation, high efficiency and energy saving, long service life, and are widely used. With oxygen, chemical technology and high-altitude oxygen supply, together with an oxygen generator, a simple and safe high-pressure oxygen system is formed.

The gas cylinder filling oxygen compressor is suitable for inlet pressure 3-4barg (40-60psig) and exhaust pressure 150barg (2150psig)

The 15NM3-60NM3/hour small PSA oxygen generation system provides clean oxygen filling services for the oxygen supply of communities and small island hospitals, and industrial oxygen cutting. It can run continuously for 24 hours, and it can reach more than 20 bottles each time.

Features of this compressor

Four-stage compression is adopted. The water-cooled model uses a stainless steel water cooler to ensure a good cooling effect of the compressor and effectively extend the service life of key wearing parts. The intake port is equipped with a low intake pressure, and the exhaust end is equipped with an exhaust device. Each level of high pressure protection, high exhaust temperature protection, safety valve and temperature display. If the temperature is too high and overpressure, the system will alarm and stop to ensure safe operation. There is a forklift at the bottom of the compressor, which can be easily transferred to the site

Parameters

| Model | Work medium | Inlet pressure (barg) | Outlet pressure (barg) | Volum flow (NM3/h) | Motor power (KW) | Voltage/ Frequency | Inlet air/outlet air(mm) | Cooling method | Weight (kg) | Dimesion(mm) | Compressor stages |

| GOW-15/4-150 | Oxygen | 3-4 | 150 | 15 | 5.5/11 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 750 | 1550X910X1355 | 4-stage |

| GOW-16/4-150 | Oxygen | 3-4 | 150 | 16 | 5.5/11 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 750 | 1550X910X1355 | 4-stage |

| GOW-20/4-150 | Oxygen | 3-4 | 150 | 20 | 11 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 750 | 1550X910X1355 | 4-stage |

| GOW-25/4-150 | Oxygen | 3-4 | 150 | 25 | 11 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 750 | 1550X910X1355 | 4-stage |

| GOW-30/4-150 | Oxygen | 3-4 | 150 | 30 | 11 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 750 | 1550X910X1355 | 4-stage |

| GOW-35/4-150 | Oxygen | 3-4 | 150 | 35 | 11 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 750 | 1550X910X1355 | 4-stage |

| GOW-40/4-150 | Oxygen | 3-4 | 150 | 40 | 15 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 780 | 1550X910X1355 | 4-stage |

| GOW-45/3-150 | Oxygen | 3-4 | 150 | 45 | 15 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 780 | 1550X910X1355 | 4-stage |

| GOW-50/4-150 | Oxygen | 3-4 | 150 | 50 | 15 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 780 | 1550X910X1355 | 4-stage |

| GOW-50/2-150 | Oxygen | 3-4 | 150 | 50 | 18.5 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 800 | 1550X910X1355 | 4-stage |

| GOW-55/4-150 | Oxygen | 3-4 | 150 | 55 | 18.5 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 800 | 1550X910X1355 | 4-stage |

| GOW-60/4-150 | Oxygen | 3-4 | 150 | 60 | 18.5 | 380/50/3 | DN25/M16X1.5 | Air cooling/ Water cooling | 800 | 1550X910X1355 | 4-stage |

Advantages

1. Completely 100% oil-free, no oil required, stainless steel cylinder

2. Suitable for VPSA PSA oxygen source pressurization

3. No pollution, keep the gas purity unchanged

4. The quality is safe and reliable, with good stability, comparable to and replacing similar foreign brands.

5. Low purchase cost, low maintenance cost and simple operation.

6. The service life of the piston ring under low pressure condition is 4000 hours, and the service life of piston ring under high pressure condition is 1500-200 hours

7. Brand motor, you can specify the brand, such as Siemens or ABB brand

8. Supply the Japanese market to meet Japan's demanding quality requirements

9. According to the customer's specific working conditions, the compressor is designed for single-stage compression, two-stage compression, three-stage compression and four-stage compression.

10. Low speed, long life, average speed 260-400RPM,

11. Low noise, average noise is less than 75dB, can work quietly in the medical field

12. Continuous continuous heavy-duty operation, stable operation for 24 hours without shutdown (depending on the specific model)

Picture dispaly

If you want us to provide you with detailed technical design and quotation, please provide the following technical parameters, and we will reply to your email or phone within 24 hours.

1.Flow: _____ Nm3 / hour

2.Inlet pressure: _____Bar(MPa)

3.Outlet pressure: _____Bar(MPa)

4. Gas medium: _____