Are you in the oil and gas, iron milling, chemical or petrochemical industry? Are you handling any kind of industrial gases? Then you will be looking for high durable and reliable compressors which work in the toughest of environments.

1. Why you choose process gas screw compressor?

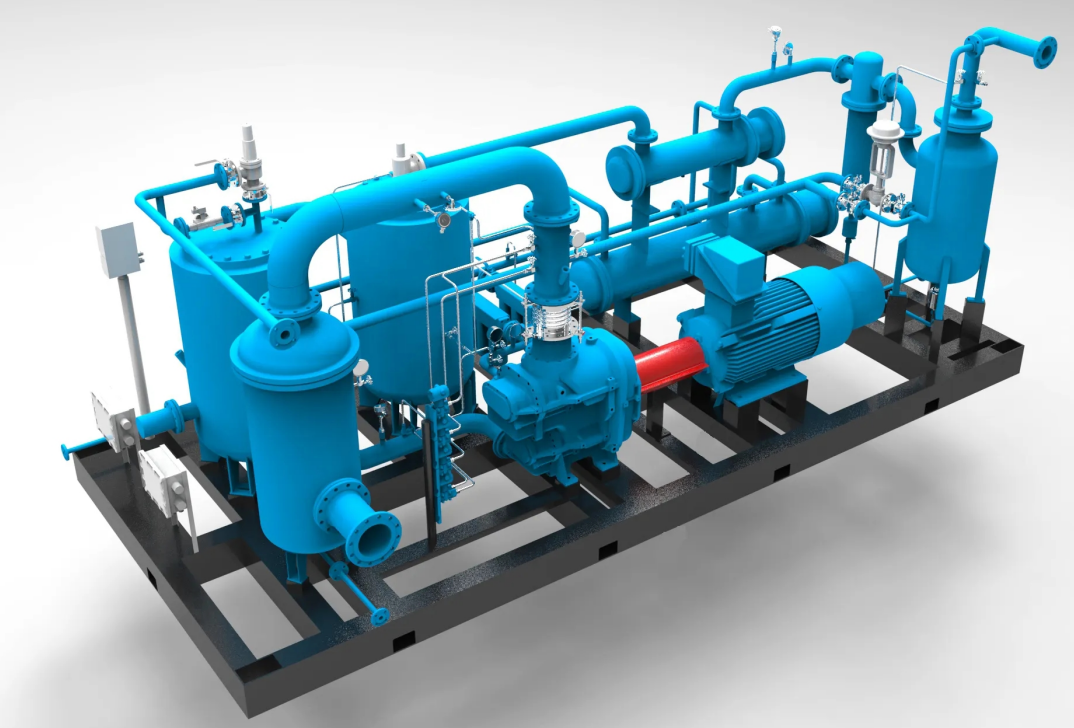

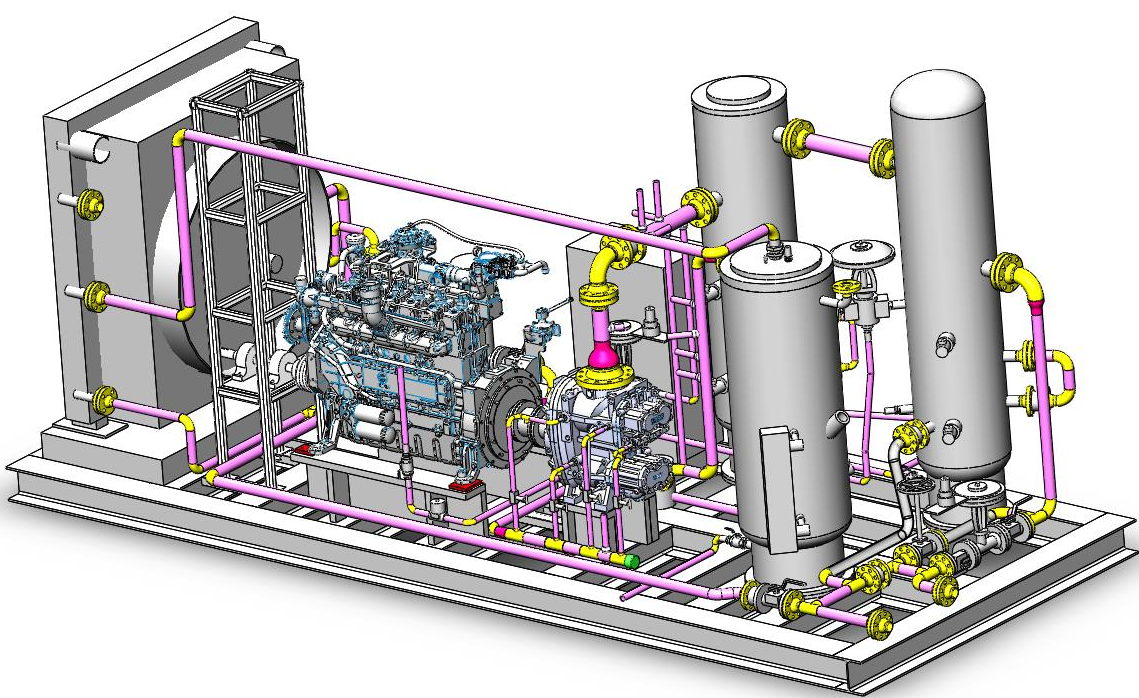

The process gas screw compressors offered by HUAYAN can handle highly contaminated gases and gas mixtures that would normally reduce the availability and shorten the lifetime of other types of compressors. Wide fluctuations in gas composition and associated molecular weight do not influence a screw compressor’s mechanical behavior. Relatively low tip speeds enable both the compression of dust-laden gases as well as the injection of liquids into the compression chamber for cooling and washing.

2. Benefits of process gas screw compressor

– Highest availability and reliability based on very robust design

– Customized for specific process requirements

– Ideal for variable molecular weights

– Dirty and polymerising gases

– Long overhaul intervals

– Low OPEX costs

3. Applications of process gas screw compressor

Screw compressors cover the full spectrum of oil & gas and lndustrial applications including:

– Oil & gas production

– Refinery

– Flare gas recovery

– Butadiene extraction

– Styrene monomer production

– Hydrogen purification

– Power generation

– Soda Ash production

– Steel production (Coke Oven Gas)

– Refrigeration

– Hydrogen Sulfide

– Methyl chloride

– Chlorine

– Hydrocarbon Mix

4. HUAYAN process gas screw compressor specifications

Post time: Jul-06-2022