We have Exported LPG compressor to Russia on May 16th 2022.

This ZW series of oil-free compressors is one of the first products produced by our factory in China. The compressors have the advantage of low rotating speed, high component strength, stable operation, long service life and convenient maintenance. It is consist of compressor, gas-liquid separator, filter, two-position four-way valve, safety valve, check valve, explosion-proof motor and base etc. It has the characteristics of small size, light weight, low noise, good sealing, easy installation and easy operation.

This compressor is mainly used for unloading, loading, dumping, residual gas recovery and residual liquid recovery of LPG/C4, propylene and liquid ammonia. It is widely used in gas, chemical, energy and other industries, and is a key equipment in gas, chemical, energy and other industries.

Propane-Butane Mix Compressor

| Number | Type | Power(kW) | Dimension (mm) | Loading or unloading (t/h) |

| 1 | ZW-0.6/16-24 | 11 | 1000×680×870 | ~15 |

| 2 | ZW-0.8/16-24 | 15 | 1000×680×870 | ~20 |

| 3 | ZW-1.0/16-24 | 18.5 | 1000×680×870 | ~25 |

| 4 | ZW-1.5/16-24 | 30 | 1400×900×1180 | ~36 |

| 5 | ZW-2.0/16-24 | 37 | 1400×900×1180 | ~50 |

| 6 | ZW-2.5/16-24 | 45 | 1400×900×1180 | ~60 |

| 7 | ZW-3.0/16-24 | 55 | 1600×1100×1250 | ~74 |

| 8 | ZW-4.0/16-24 | 75 | 1600×1100×1250 | ~98 |

| 9 | VW-6.0/16-24 | 132 | 2400×1700×1550 | ~147 |

Inlet pressure:≤1.6MPa

Outlet pressure: ≤2.4MPa

Max differential pressure: 0.8MPa

Maximum Instantaneous Pressure Ratio:≤4

Cooling method: Air cooling

The unloading volume is calculated according to the inlet pressure of 1.6MPa, the outlet pressure of 2.4MPa, the inlet temperature of 40 ℃ , and the density of propylene liquid of 614kg/m3. When the working conditions change, the unloading volume will change accordingly, which is for reference only.

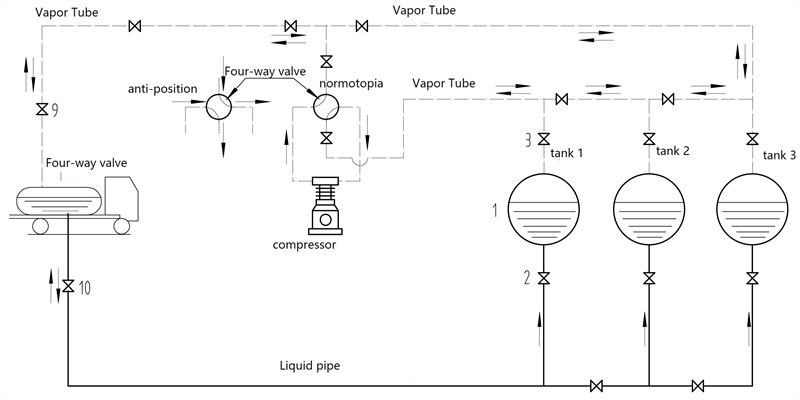

Piping and Instrumentation Diagram of gas unloading

Liquid delivery

At the beginning, open the liquid phase pipeline between the tanker and the storage tank. If the liquid level in the tanker is higher than the storage tank, it will automatically flow into the storage tank. When the balance is reached, the flow will stop. If the liquid phase of the tanker is lower than the storage tank, directly start the compressor, the four-way valve is in the positive position, and the gas is extracted from the storage tank by the compressor and then discharged into the tanker. At this time, the pressure in the tank car rises, the pressure in the storage tank drops, and the liquid in the tank car flows into the storage tank. (as shown below)

LPG compressors are mainly used for liquefied petroleum gas or gas with similar properties to convey and pressurize, and are also ideal equipment for chemical enterprises to pressurize and recover gas.

Post time: May-20-2022