Maybe you only know about air compressors because it is the most widely used type of compressor. However, oxygen compressors, nitrogen compressors and hydrogen compressors are also common compressors. This article highlights the differences between an air compressor and an oxygen compressor to help you understand which type of compressor you want.

What is an air compressor?

An air compressor is a device that stores power (using an electric motor, diesel or gasoline engine, etc.) as potential energy in pressurized air (ie, compressed air). Through one of several methods, the air compressor powers more and more compressed air, which is then held in the tank until called into use. The compressed air energy contained in it can be used in a variety of applications, utilizing the kinetic energy of the air as it is released, depressurizing the container. When the tank pressure reaches its lower limit again, the air compressor turns and repressurizes the tank. Since it can be used for any gas/air while the pump is working in liquid it must be differentiated from the pump.

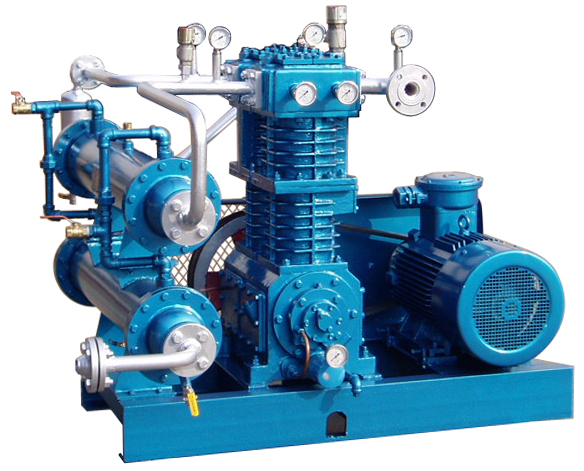

What is an oxygen compressor?

An oxygen compressor is a compressor used to pressurize oxygen and supply it. Oxygen is a violent accelerant that can easily cause fires and explosions.

Difference Between Air Compressor and Oxygen Compressor

The air compressor compresses the air directly into the container. Air compressed by an air compressor consists of two parts: 78% nitrogen; 20-21% oxygen; 1-2% water vapor, carbon dioxide and other gases. The air in the "component" does not change after compression, but the size of the space these molecules occupy.

Oxygen compressors contain oxygen and are compressed directly from oxygen. The compressed gas is high-purity oxygen and takes up little space.

The difference between an oxygen compressor and an air compressor is to make sure it is oil free.

1. In the oxygen compressor, all parts that come into contact with the oxygen in the screw air compressor must be strictly degreased and degreased before being loaded. Clean with tetrachloride to avoid explosive carbon.

2. Oxygen press maintenance personnel must wash their hands first when replacing or repairing the parts that come into contact with compressed oxygen. Workbenches and spare parts cabinets must also be clean and oil-free.

3. The amount of lubricating water for the oxygen compressor should not be too small or watery to avoid a sharp rise in the temperature of the cylinder; for blasting the cylinder and the amount of cooling water for the cooler must be lower than the high-pressure oxygen flow.

4. When the pressure change of the oxygen compressor is abnormal, the related valve should be replaced or repaired in time to avoid the continuous rise of the cylinder temperature.

5. Pay attention to the working state of the upper and the letter of the middle seat of the lower sealed oxygen compressor. If the sealing condition is poor, the fill port can be replaced by the piston rod cylinder at a time to prevent the oil from being lifted to the oxygen compressor.

You probably already understand the type of compressor you need after reading this article. If you need it, you can flip through our website and choose from a variety of models. If you have any questions, please feel free to contact with us .

Post time: Jan-15-2022