Hydrogen diaphragm compressor, as an important gas compression equipment, plays a crucial role in multiple fields. The following is a detailed explanation of the use of hydrogen diaphragm compressors, which will follow a clear structure and refer to as many relevant numbers and information as possible in the article.

1、 Basic Overview of Hydrogen Diaphragm Compressors

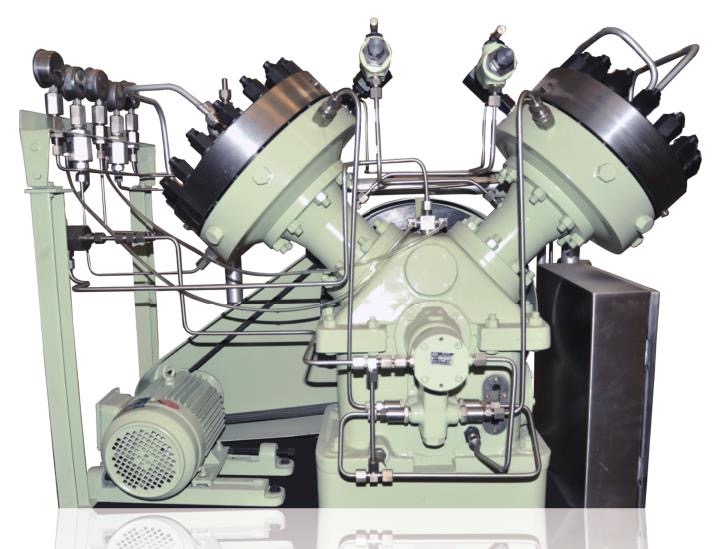

Hydrogen diaphragm compressor is a special type of compressor, which mainly uses a diaphragm for gas compression and transportation. Due to its unique structure and working principle, hydrogen diaphragm compressors have significant advantages in compressing high-purity, flammable and explosive, corrosive, and high-pressure gases.

2、 Application fields of hydrogen diaphragm compressors

2.1. Hydrogen energy field

(1) Hydrogen filling: Hydrogen diaphragm compressors play an important role in hydrogen filling stations, as they can extract hydrogen from storage tanks and compress it to a high-pressure state for long-distance transportation or storage. In hydrogen refueling stations, hydrogen diaphragm compressors are also used to charge hydrogen into fuel cell vehicles.

(2) Hydrogen refueling stations: With the rapid development of the hydrogen energy industry, as an important link in the hydrogen energy industry chain, the demand for hydrogen diaphragm compressors is also increasing. Hydrogen diaphragm compressors are mainly used in hydrogen refueling stations to compress hydrogen to the required pressure to meet the hydrogenation needs of fuel cell vehicles.

(3) Residual hydrogen recovery: In industrial production processes, a large amount of residual hydrogen may be generated. By using a hydrogen diaphragm compressor, these residual hydrogen can be compressed and recovered, achieving resource reuse.

(4) Integrated hydrogen production and hydrogenation: Hydrogen diaphragm compressors also play an important role in the integrated hydrogen production and hydrogenation system. It can compress and transport the hydrogen gas generated during the hydrogen production process to meet the needs of hydrogen refueling stations or other hydrogen consuming equipment.

2.2. Petrochemical industry

In the field of petrochemicals, hydrogen diaphragm compressors are mainly used to compress and transport various high-purity gases, precious and rare gases, toxic and harmful gases, and corrosive gases. These gases have a wide range of applications in petrochemical production processes, such as catalyst regeneration, hydrocracking, dehydrogenation, and other processes.

2.3. Other fields

In addition to the fields of hydrogen energy and petrochemicals, hydrogen diaphragm compressors are also widely used in industries such as nuclear power, food and medicine, electronics, materials industry, national defense and military industry, and scientific testing. In these fields, hydrogen diaphragm compressors are used to compress and transport various special gases to meet the needs of different process processes.

3、 Technical characteristics of hydrogen diaphragm compressors

The hydrogen diaphragm compressor has the characteristics of high compression ratio, good sealing performance, and the compressed gas is not contaminated by lubricating oil and other solid impurities. These characteristics give hydrogen diaphragm compressors significant advantages in compressing high-purity, flammable and explosive, corrosive, and high-pressure gases. At the same time, with the progress and development of science and technology, hydrogen diaphragm compressors are developing towards higher pressure and larger displacement to meet the needs of different fields for gas compression and transportation.

In summary, hydrogen diaphragm compressors play an important role in multiple fields such as hydrogen energy and petrochemicals. With the rapid development of the hydrogen energy industry and technological progress, the application prospects of hydrogen diaphragm compressors will be even broader.

Post time: Jul-04-2024