Methane Biogas Reciprocating Piston Compressor

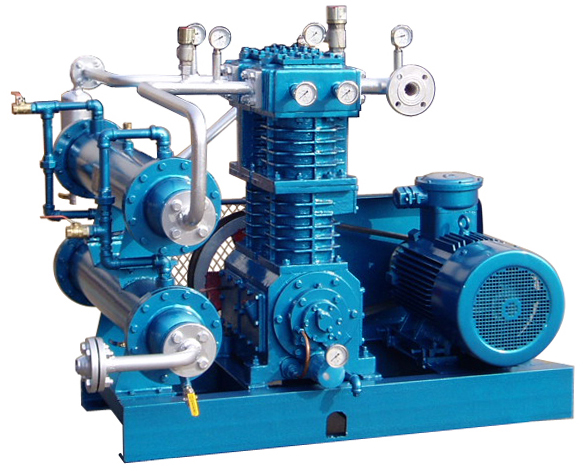

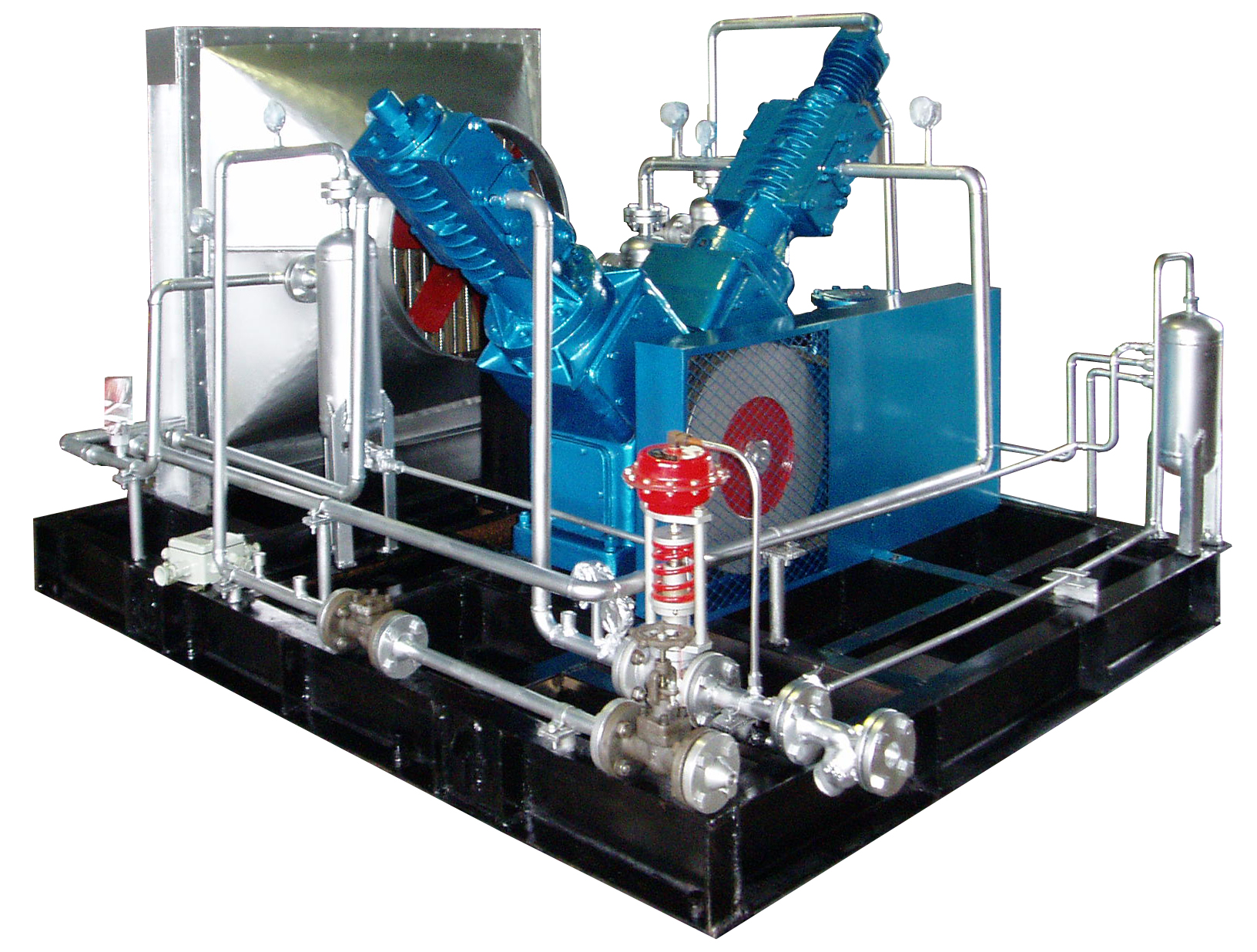

METHANE BIOGAS COMPRESSOR-REFERENCE PICTURE

A piston compressor is a kind of piston reciprocating motion to make gas pressurization and a gas delivery compressor mainly consists of a working chamber, transmission parts, body, and auxiliary parts. The working chamber is directly used to compress the gas, the piston is driven by the piston rod in the cylinder for reciprocating motion, The volume of the working chamber on both sides of the piston changes in turn, and the volume decreases on one side of the gas due to the pressure increase through the valve discharge, the volume increases on one side due to the reduction of air pressure through the valve to absorb the gas.

We have various gas compressors, such as Hydrogen compressors, Nitrogen compressors, Natural gas compressors, Biogas compressors, Ammonia compressors, LPG compressors, CNG compressors, Mix gas compressors, and so on.

BIOGAS COMPRESSOR

The gas compressor is suitable for a variety of gas pressurization, transportation, and other working conditions. Suitable for medical, industrial, flammable explosive, corrosive, and toxic gases.

The sources of biogas mainly include landfill fermentation, catering waste treatment, and other methods. The main content of biogas is methane, carbon dioxide, and other relatively low-content media. The biogas can be loaded into vehicles for users to use through compressor boosting.

A. Classified by structure:

Piston compressors have four main types: Z, V, etc.;

B. Classified by compressed media:

It can compress rare and precious gases, flammable and explosive gases, etc.

C. Classified by sports organization:

Crankshaft connecting rod, crank slider, etc.;

D. Classified by cooling method:

Water cooling, oil cooling, rear air cooling, natural cooling, etc.;

E. Classified by lubrication method:

Pressure lubrication, splash lubrication, external forced lubrication, etc.

Technical parameters and specifications

| No | Model | Gas | Gas flow (Nm3/h) | Inlet pressure (Mpa) | Outlet pressure (Mpa) | Note |

| 1 | VW-7/1-45 | Biogas compressor | 700 | 0.1 | 4.5 | |

| 2 | VW-3.5/1-45 | 350 | 0.1 | 4.5 | ||

| 3 | ZW-0.85/0.16-16 | 50 | 0.016 | 1.6 | ||

| 4 | VW-5/1-45 | 500 | 0.1 | 4.5 | ||

| 5 | VW-5.5/4.5 | 280 | Atmospheric pressure | 0.45 | ||

| 6 | ZW-0.8/2-16 | 120 | 0.2 | 1.6 |

After Sales Service

1. Quick response within 2 to 8 hours, with a reaction rate exceeding 98%;

2. 24-hour telephone service, please feel free to contact us;

3. The whole machine is guaranteed for one year (excluding pipelines and human factors);

4. Provide consulting service for the service life of the whole machine, and provide 24-hour technical support via email;

5. On-site installation and commissioning by our experienced technicians;

FAQ

1. How to get a prompt quotation for a gas compressor?

1)Flow Rate/Capacity: ___ Nm3/h

2)Suction/ Inlet Pressure: ____ Bar

3)Discharge/Outlet Pressure:____ Bar

4)Gas Medium:_____

5)Voltage and Frequency: ____ V/PH/HZ

2. How long is the delivery time?

Delivery time is around the 30-90 days.

3. What about the voltage of products? Can they be customized?

Yes, the voltage can be customized according to your inquiry.

4. Can you accept OEM orders?

Yes, OEM orders are highly welcome.

5. Will you provide some spare parts for the machines?

Yes, we will.