GZ series High Pressure H2 Diaphragm Compressor for H2 Refueling Station

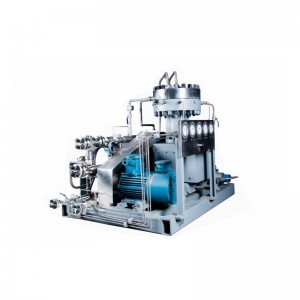

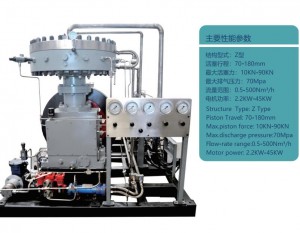

GZ SERIES DIAPHRAGM COMPRESSOR-REFERENCE PICTURE

The Diaphragm Compressor is a positive displacement compressor with a special structure. It is the highest level compression method in the gas compression field. This compression method has no secondary pollution and has very good protection for the compressed gas. It has a large compression ratio, has good sealing performance, and the compressed gas is not polluted by lubricating oil and other solid impurities. Therefore, it is suitable for compressing high-purity, rare and precious, flammable, explosive, toxic and harmful, corrosive, and high-pressure gases. This compression method is usually designated internationally to compress high-purity gases, flammable and explosive gases, toxic gases, and oxygen. and many more.

A. Classified by structure:

Diaphragm compressors have four main types: Z, V, D, L, etc.;

B. Classified by diaphragm material:

Diaphragm materials of diaphragm compressors are metal diaphragm (including black metal and non-ferrous metal) and non-metal diaphragms;

C. Classified by compressed media:

It can compress rare and precious gases, flammable and explosive gases, high-purity gases, corrosive gases, etc.

D. Classified by sports organization:

Crankshaft connecting rod, crank slider, etc.;

E. Classified by cooling method:

Water cooling, oil cooling, rear air cooling, natural cooling, etc.;

F. Classified by lubrication method:

Pressure lubrication, splash lubrication, external forced lubrication, etc.

GZ SERIES DIAPHRAGM COMPRESSOR-PARAMETER TABLE

| GZ series diaphragm compressor parameter table | ||||||||

| Model | Cooling water (L/h) | Flow (Nm³/h) | Inlet pressure (MPa) | Outlet pressure (MPa) | Dimensions L×W×H(mm) | Weight (kg) | Motor Power (kW) | |

| 1 | GZ-2/3 | 1000 | 2.0 | 0.0 | 0.3 | 1200×700×1100 | 0 | 2.2 |

| 2 | GZ-5/0.5-10 | 200 | 5.0 | 0.05 | 1.0 | 1400×740×1240 | 650 | 2.2 |

| 3 | GZ-5/13-200 | 400 | 5.0 | 1.3 | 20 | 1500×760×1200 | 750 | 4.0 |

| 4 | GZ-15/3-19 | 500 | 15 | 0.3 | 1.9 | 1400×740×1330 | 750 | 4.0 |

| 5 | GZ-30/5-10 | 500 | 30 | 0.5 | 1.0 | 1400×740×1330 | 700 | 3.0 |

| 6 | GZ-50/9.5-25 | 600 | 50 | 0.95 | 2.5 | 1500×760×1200 | 750 | 5.5 |

| 7 | GZ-20/5-25 | 600 | 20 | 0.5 | 2.5 | 1400×760×1600 | 650 | 4.0 |

| 8 | GZ-20/5-30 | 1000 | 20 | 0.5 | 3.0 | 1400×760×1600 | 650 | 5.5 |

| 9 | GZ-12/0.5-8 | 400 | 12 | 0.05 | 0.8 | 1500×760×1200 | 750 | 4.0 |

| 10 | GZ—5/0.5-8 | 200 | 5.0 | 0.05 | 0.8 | 1400×740×1240 | 650 | 2.2 |

| 11 | GZ-14/39-45 | 500 | 14 | 3.9 | 4.5 | 1000×460×1100 | 700 | 2.2 |

| 12 | GZ-60/30-40 | 2100 | 60 | 3.0 | 4.0 | 1400×800×1300 | 750 | 3.0 |

| 13 | GZ-80/59-65 | 500 | 80 | 5.9 | 6.5 | 1200×780×1200 | 750 | 7.5 |

| 14 | GZ-30/7-30 | 1000 | 30 | 0.7 | 3.0 | 1400×760×1600 | 650 | 5.5 |

| 15 | GZ-10/0.5-10 | 200 | 10 | 0.05 | 1.0 | 1400×800×1150 | 500 | 4.0 |

| 16 | GZ-5/8 | 200 | 5.0 | 0.0 | 0.8 | 1400×800×1150 | 500 | 3.0 |

| 17 | GZ-15/10-100 | 600 | 15 | 1.0 | 10 | 1400×850×1320 | 1000 | 5.5 |

| 18 | GZ-20/8-40 | 1000 | 20 | 0.8 | 4.0 | 1400×850×1320 | 1000 | 4.0 |

| 19 | GZ-20/32-160 | 1000 | 20 | 3.2 | 16 | 1400×850×1320 | 1000 | 5.5 |

| 20 | GZ-30/7.5-25 | 1000 | 30 | 0.75 | 2.5 | 1400×850×1320 | 1000 | 7.5 |

| 21 | GZ-5/0.1-7 | 1000 | 5.0 | 0.01 | 0.7 | 1200×750×1000 | 600 | 2.2 |

| 22 | GZ-8/5 | 1000 | 8.0 | 0.0 | 0.5 | 1750×850×1250 | 1000 | 3.0 |

| 23 | GZ-11/0.36-6 | 400 | 11 | 0.036 | 0.6 | 1500×760×1200 | 750 | 3.0 |

| 24 | GZ-3/0.2 | 1000 | 3.0 | 0.0 | 0.02 | 1400×800×1300 | 1000 | 2.2 |

| 25 | GZ-80/20-35 | 1500 | 80 | 2.0 | 3.5 | 1500×800×1300 | 900 | 5.5 |

| 26 | GZ-15/30-200 | 1000 | 15 | 3.0 | 20 | 1400×1000×1200 | 800 | 4.0 |

| 27 | GZ-12/4-35 | 1000 | 12 | 0.4 | 3.5 | 1500×1000×1500 | 800 | 5.5 |

| 28 | GZ-10/0.5-7 | 400 | 10 | 0.05 | 0.7 | 1500×760×1200 | 750 | 3.0 |

| 29 | GZ-7/0.1-6 | 1000 | 7.0 | 0.01 | 0.6 | 1200×900×1200 | 800 | 3.0 |

| 30 | GZ-20/4-20 | 1000 | 20 | 0.4 | 2.0 | 1400×850×1320 | 750 | 2.2 |

| 31 | GZF-42/120-350 | 1200 | 42 | 12 | 35 | 900×630×834 | 420 | 5.5 |

| 32 | GZ-7/0.1-6 | 1500 | 7 | 0.01 | 0.6 | 1200×900×1200 | 800 | 3.0 |

| 33 | GZ-120/80-85 | 1500 | 100 | 8.0 | 8.5 | 1200×900×1200 | 800 | 4.0 |

| 34 | GZ-5/6-10 | 1000 | 5.0 | 0.6 | 1.0 | 1200×700×1100 | 700 | 2.2 |

| 35 | GZ-7/50-350 | 1000 | 7.0 | 5.0 | 35 | 1150×700×1100 | 450 | 3.0 |

| 36 | GZ-20/7-30 | 1000 | 20 | 0.7 | 3.0 | 1400×760×1100 | 750 | 4.0 |

| 37 | GZ-62/40-56 | 1500 | 62 | 4.0 | 5.6 | 1200×700×1100 | 450 | 3.0 |

| 38 | GZ-15/10-12 | 1500 | 15 | 1.0 | 1.2 | 1200×700×1100 | 500 | 3.0 |

| 39 | GZ-14/6-20 | 1000 | 14 | 0.6 | 2.0 | 1200×700×1100 | 500 | 2.2 |

| 40 | GZ-350/120-450 | 1000 | 350 | 5-20 | 450 | 2350×1850×1100 | 7000 | 37 |

| 41 | GZ-936/8-8.3 | 2000 | 936 | 0.8 | 0.83 | 2100×1500×1700 | 2000 | 15 |

SUBMIT INQUIRY PARAMETERS

If you want us to provide you with detailed technical design and quotation, please provide the following technical parameters, and we will reply to your email or phone within 24 hours.

1.Flow: _____ Nm3 / hour

2.Inlet pressure: _____Bar(MPa)

3.Outlet pressure: _____Bar(MPa)

4. Gas medium: _____

We can customize a variety of compressors. Please send the above parameters to email: Mail@huayanmail.com