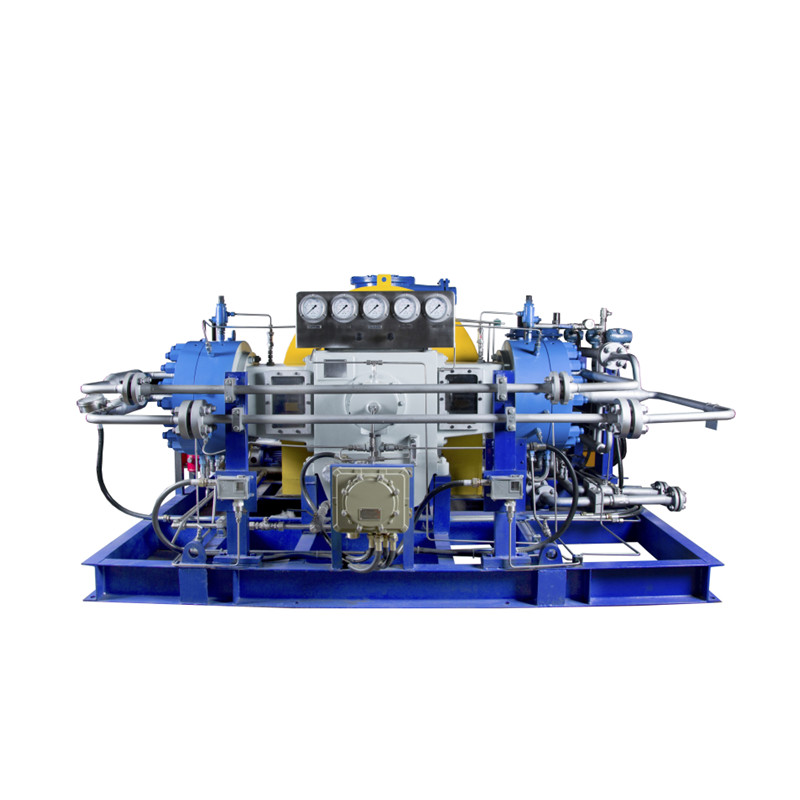

Stable Operation Mixed Gas Nitrogen N2 Carbon Dioxide CO2 Diaphragm Compressor Diaphragm Compressor Supplier

Our company specialize in producing various kinds of compressors, such as:Diaphragm compressor,Piston compressor, Air compressors,Nitrogen generator,Oxygen generator ,Gas cylinder,etc. All products can be customized according to your parameters and other requirements.

Diaphragm compressor according to the needs of the user, choose the right type of compressor to meet the needs of the user. The diaphragm of the metal diaphragm compressor completely separates the gas from the hydraulic oil system to ensure the purity of the gas and no pollution to the gas. At the same time, advanced manufacturing technology and accurate membrane cavity design technology are adopted to ensure the service life of the diaphragm compressor diaphragm. No pollution: the metal diaphragm group completely separates the process gas from the hydraulic oil and lubricating oil parts to ensure the gas purity.

Main Structure

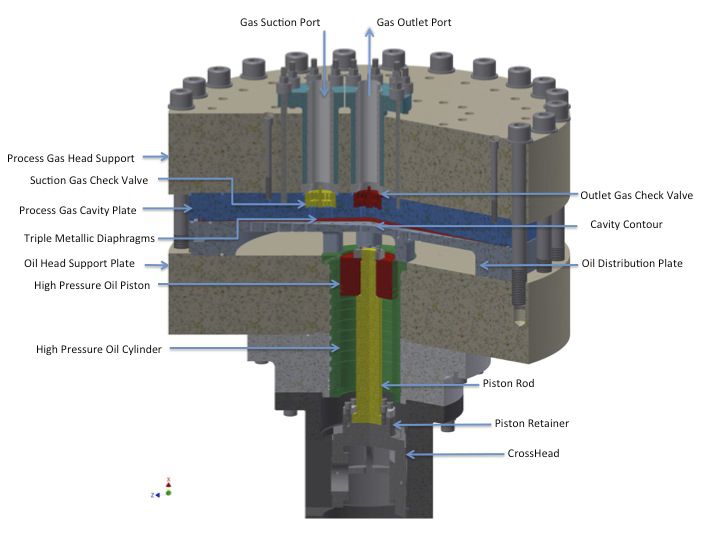

Diaphragm compressor structure is mainly composed of motor, base, crankcase, crankshaft linkage mechanism, cylinder components, crankshaft connecting rod, piston, oil and gas pipeline, electric control system and some accessories.

Gas Media type

Our compressors can compress ammonia, propylene, nitrogen, oxygen, helium, hydrogen, hydrogen chloride, argon, hydrogen chloride, hydrogen sulfide, hydrogen bromide, ethylene, acetylene, etc.(Nitrogen diaphragm compressor,bottle filling compressor,oxygen diaphragm compressor)

GD Model Simple Description

GD diaphragm compressor is a special structure of the volumetric compressor, is the highest level of compression in the field of gas compression, this compression method Without secondary pollution, it can ensure the purity of gas is more than 5, and it has very good protection against compressed gas. It has the characteristics of large compression ratio, good sealing performance, and the compressed gas is not polluted by lubricating oil and other solid impurities. Therefore, it is suitable for compressing high-purity, rare and precious, flammable, explosive, toxic, harmful, corrosive and high-pressure gases. The compression method is generally specified in the world for compressing high-purity gas, flammable and explosive gas, toxic gas and oxygen. Etc. (such as nitrogen diaphragm compressor, oxygen diaphragm compressor, hydrogen sulfide diaphragm compressor, argon diaphragm compressor, etc.).

GD diaphragm compressor for my company independent research and development of large diaphragm compressor, its advantages are: high compression ratio, large displacement, large piston force, stable running, high exhaust pressure, etc, has been widely used and petroleum chemical industry and nuclear power plant, and so on,.Two GD type diaphragm compressor cylinder arrangement for symmetrically arranged in parallel, more suitable for the petrochemical and nuclear power plant such as uninterrupted operation for a long time, because of the cylinder body symmetry, run up against other arrangement of diaphragm compressor is the most stable operation, running, small vibration from the ground clearance is more convenient in maintenance.

Advantages

No leakage: the compressor membrane head is sealed by static "O" ring. The O "ring is made of elastic material, with long service life and no dynamic seal to ensure no leakage during gas compression.

Corrosion resistance: the compressor membrane head can be made of 316L stainless steel, the diaphragm is made of 301 stainless steel.

Small tightening torque: "O" ring seal, can reduce flange bolt tightening torque, reduce shutdown maintenance time.

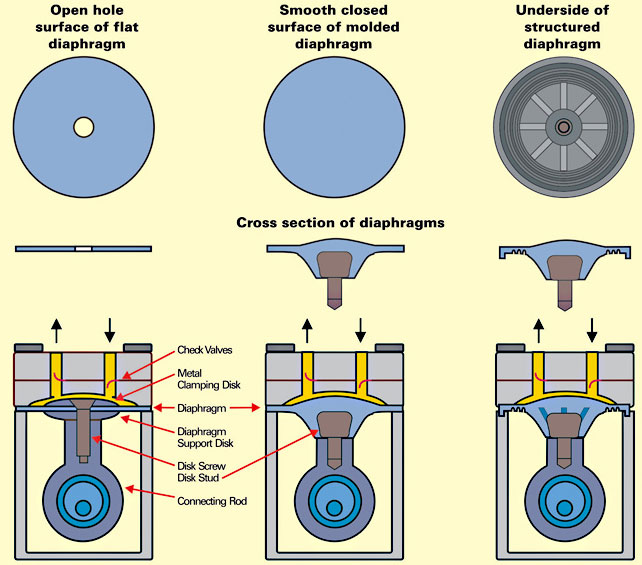

The compressor is consists of a three pieces of diaphragms. The diaphragm is clamped along the surrounding area by the hydraulic oil side and the process gas side of the process. The diaphragm is driven by the hydraulic driver in the film head to achieve the compression and transportation of the gas. The main body of the diaphragm compressor consists of two systems: the hydraulic oil system and the gas compression system, and the metal membrane separates these two systems.

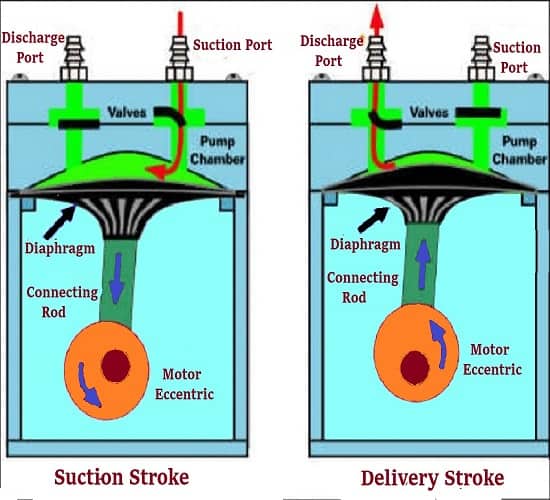

Basically, the structure of the diaphragm compressor is divided into two parts: the hydraulic framework and the pneumatic force framework. During the compression process, there are two steps: the suction stroke and the delivery stroke.

GD series diaphragm compressor :

Structure type : D type

Piston Travel : 130-210mm

Max Piston force : 40KN-160KN

Max discharge Pressure : 100MPa

Flow Rate Range :30-2000Nm3/h

Motor Power : 22KW-200KW

Customized is accepted , Pls provide the following information to us :

1.Flow rate: _______Nm3/h

2.Gas Media : ______ Hydrogen or Natural Gas or Oxygen or other gas ?

3.Inlet pressure: ___bar(g)

4.Inlet temperature:_____℃

5.Outlet pressure:____bar(g)

6.Outlet temperature:____℃

7.Installation location: _____indoor or outdoor?

8.Location ambient temperature: ____℃

9.Power supply: _V/ _Hz/ _3Ph?

10.Cooling method for gas: air cooling or water cooing?

Wide variety and types of diaphragm compressor can be manufactured by our company such as hydrogen compressor , nitrogen compressor , helium compressor , natural gas compressor and etc .

Outlet pressure at 50bar 200 bar, 350 bar (5000 psi), 450 bar, 500 bar, 700 bar (10,000 psi), 900 bar (13,000 psi) and other pressure can be customized .

Specfication:

| Parameter Table Of GD Series Diaphragm Compressor | ||||||||

| Model | Cooling water consumption t/h | Volume Flow Nm3/h | Suction pressure (MPa) | Exhaust pressure (MPa) | Dimension LxWxH(mm) | Weight (t) | Motor Power (kW) | |

| 1 | GD-120/4-80 | 3.0 | 120 | 0.4 | 8.0 | 3000x1600x1400 | 30 | |

| 2 | GD-130/0.98-11 | 3.0 | 130 | 0.098 | 1.1 | 3000x1800x1600 | 4.0 | 30 |

| 3 | GD-150/2-20 | 3.0 | 150 | 0.2 | 2.0 | 3000x1800x1600 | 4.0 | 37 |

| 4 | GD-100/0.1-5 | 4.0 | 100 | 0.01 | 0.5 | 2800X1500X1500 | 3.0 | 18.5 |

| 5 | GD-100/5.5-200 | 5.0 | 100 | 0.55 | 20 | 3200X2000X1600 | 4.5 | 45 |

| 6 | GD-80/0.12-4 | 5.0 | 80 | 0.012 | 0.4 | 2800x1600x 1500 | 3.8 | 15 |

| 7 | GD-60/0.3-6 | 4.0 | 60 | 0.03 | 0.6 | 2800x1600x1500 | 4.0 | 15 |

| 8 | GD-70/0.1-8 | 3.8 | 70 | 0.01 | 0.8 | 3000 x 1600x1250 | 5.0 | 18.5 |

| 9 | GD-40/0.02-160 | 5.0 | 40 | 0.02 | 16 | 2800x1460x1530 | 3.0 | 22 |

| 10 | GD-100/0.5-6 | 2.0 | 100 | 0.05 | 0.6 | 3000x2000x1560 | 6.0 | 18.5 |

| 11 | GD-36/1-150 | 4.0 | 36 | 0.1 | 15 | 3000x1500x1500 | 4.0 | 45 |

| 12 | GD-35/0.7-300 | 4.0 | 35 | 0.07 | 30 | 3000x1600x1500 | 4.0 | 22 |

| 13 | GD-500/15-35 | 4.5 | 500 | 1.5 | 3.5 | 3000x2000x1700 | 4.0 | 45 |

| 14 | GD-150/15-210 | 4.5 | 150 | 1.5 | 21 | 3200x1700x1600 | 4.0 | 45 |

| 15 | GD-120/8-220 | 4.5 | 120 | 0.8 | 22 | 3200x1700x1600 | 3.8 | 45 |

| 16 | GD-100/9 | 4.5 | 100 | 0.0 | 0.9 | 3200x1700x1800 | 4.5 | 22 |

| 17 | GD-100/1.5-150 | 4.5 | 100 | 0.15 | 15 | 3200x1700x1800 | 4.5 | 45 |

| 18 | GD-40/30 | 4.5 | 40 | 0.0 | 3.0 | 3200x1700x1800 | 4.0 | 18.5 |

| 19 | GD-200/10-15-90 | 4.5 | 200 | 1.0-1.5 | 9.0 | 3200x1800x1600 | 4.0 | 37 |

| 20 | GD-100/7-150 | 4.0 | 100 | 0.7 | 15 | 3000x1800x 1600 | 4.0 | 55 |

| 21 | GD-25/-0.1-47 | 4.0 | 25 | -0.01 | 4.7 | 3000x1800x1600 | 4.0 | 15 |

| 22 | GD-45/0.5-100 | 4.0 | 45 | 0.05 | 10 | 3000x1800x1600 | 4.0 | 30 |

| 23 | GD-30/0.1-160 | 4.0 | 30 | 0.01 | 16 | 3000x1800x1600 | 4.0 | 18.5 |

| 24 | GD-120/2.5-70 | 4.0 | 120 | 0.25 | 7.0 | 3000x1800x1600 | 4.0 | 37 |

| 25 | GD-135/10-210 | 4.0 | 135 | 1.0 | 21 | 3000x1600x1400 | 4.0 | 37 |

| 26 | GD-60/40-350 | 4.5 | 60 | 4.0 | 35 | 3000x1800x1600 | 4.0 | 30 |

| 27 | GD-95/10-350 | 4.0 | 95 | 1.0 | 35 | 3000x1600x1400 | 4.0 | 37 |

| 28 | GD-220/11-90 | 4.0 | 220 | 1.1 | 9.0 | 3000x1800x1600 | 4.0 | 37 |

| 29 | GD-300/15-220 | 4.5 | 300 | 1.5 | 22 | 3600x2200x1700 | 5.0 | 75 |

| 30 | GD-300/13-210 | 5.0 | 300 | 1.3 | 21 | 3500x2300x1800 | 6.0 | 75 |

| 31 | GD-120/12-350 | 6.5 | 120 | 1.2 | 35 | 3500x2300x1600 | 8.5 | 45 |

| 32 | GD-165/10-250 | 8.0 | 165 | 1.0 | 25 | 3500x2300x1500 | 8.5 | 55 |

| 33 | GD-120/8-350 | 6.5 | 120 | 0.8 | 35 | 3500x2300x1600 | 8.5 | 45 |

| 34 | GD-800/210-320 | 8.0 | 800 | 21 | 32 | 3500x2300x1500 | 8.5 | 37 |

| 35 | GD-420/8-39 | 6.5 | 420 | 0.8 | 3.9 | 3600x2500x1700 | 6.0 | 75 |

| 36 | GD-370/20-200 | 4.5 | 370 | 2.0 | 20 | 3600x2200x1700 | 5.0 | 75 |

| 37 | GD-350/18-210 | 4.5 | 350 | 1.8 | 21 | 3600x2200x1700 | 5.0 | 75 |

| 38 | GD-300/8-120 | 4.5 | 300 | 0.8 | 12 | 3600 x 2200 x 1700 | 5.0 | 75 |

| 39 | GD-308/4 | 10.0 | 308 | 0 | 0.4 | 4200x3200x2600 | 10.0 | 55 |

| 40 | GD-180/8.5 | 5.0 | 180 | 0 | 0.85 | 4200x3200x2600 | 10.0 | 55 |

Application of diaphragm compressor :

Application of diaphragm compressor :

Food industry, petroleum industry, chemical industry, electronics industry, nuclear power plant, aerospace, industrial equipment, medicine, scientific research .

Our Certificate : CE and ISO certification

FAQ :

Q1.How about your after-sales service?

A: Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas after-sales service.

Q2.What's payment term?

A: T/T, L/C, D/P, Western Union, Trade Assurance and etc. Also we could accept USD, RMB, GBP, Euro and other currency.

Q3 : How long is your air compressor warranty?

A: Usually 1 year /12 Months for whole compressor machine, 2years/24months for air end (except maintenance spare parts.). And we can provide further warranty if necessary.